PROJECT “VALHALA”

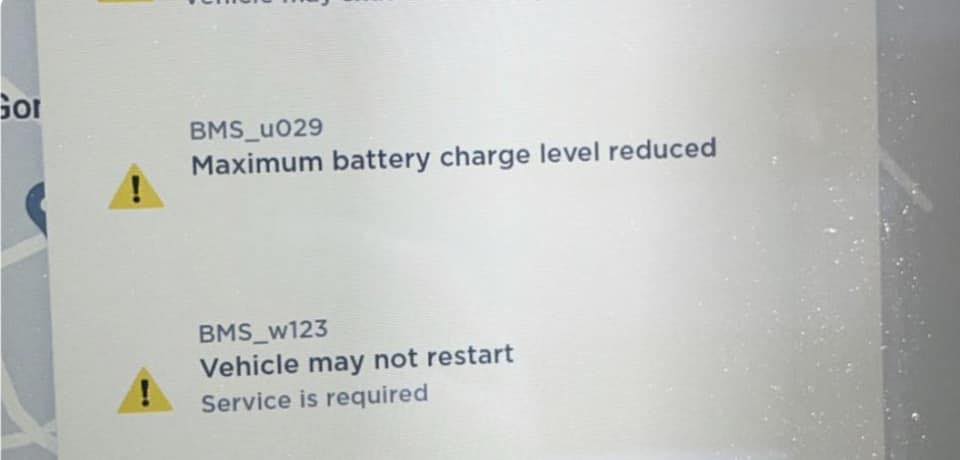

This was a mission of 3 months, a mission of a personal nature, a mission with the goal of saving the most beloved and highest quality small city EV from global cannibalization for parts. The Smart 451ED, first made by Tesla with its drive system in early 2008/09 for Daimler, was later produced by Daimler itself with the BOSCH drive system SMG180 electric motor, BOSCH AccuMotive, and “made in Germany” LiTec pouch 50Ah cells which were a fairly high technological achievement at the time. However, 10 years have passed and there are no adequate replacement cells available for these vehicles anywhere. This is also a story of the unsustainability of the automotive industry that doesn’t offer a long-term solution for replacement, and even “component level” parts, as this Smart 451ED chronically suffers from a lack of parts, especially for the battery system. The battery system, in addition to having integrated programmed BMS errors meant to bankrupt the owner, also has the long-term problem of degradation of the edge cells, which, despite active cooling and heating of the battery with antifreeze, leads to the crystallization of the electrolyte and damage to the cell layers themselves. As shown in the image below, where the edge of the cell has crystallized, risen, and started to cut into the layers of the adjacent cell.

A degraded battery pack typically has around 12 cells that need replacement to restore about 90% of the battery’s health. This is only possible if you have the materials on hand, and here lies the problem: there are no materials available. The only material that can be obtained is by cannibalizing one electric 451ED to repair 4-8 vehicles, of course, if only about 10 cells need replacement. However, in practice, the situation is even more dire because we’ve encountered cases where up to 80 out of 93 cells were damaged, which is essentially a total loss.

But for months we’ve been devising a plan and have found a solution. The solution came about quite accidentally in the form of recycled cells from a Ford Hybrid. The Ford Hybrid ended up as junk, where every hybrid arguably belongs, and we used its cells to design an entirely new battery assembly with a “block to pack” homologated and certified system that already had an integrated voltage sense PCB connector, steel housing, insulation, stress and drop test, and most importantly, state-of-the-art Samsung SDI Prismatic cells with a 6C discharge rate and 50Ah capacity. These cells perfectly match the old design in capacity, but with a significant improvement in cell body cooling, and crucially, a reduction in the overall battery weight by 50 kilograms while retaining the original battery capacity.

Thus, through mathematics, dimension measurements, and even before the start of the project, we concluded that this is the only adequate and safe solution for the reincarnation of the Smart 451ED. At the same time, it’s a solution that turns the Hybrid, the biggest misstep of the automotive industry, into something with a more noble and useful purpose than wasting resources on placebo “savings” and “cost-effective movement.” The project began as follows:

And in the end, it concluded like this and successfully operated from the first attempt:

In the entire process, we recycled absolutely everything. We utilized the original protective aluminum cage which served as the edge shield and holder for the original cells. The original “coolant plates” radiators were used, as were the original wiring for the 451 battery and the original wiring of the Ford block with “Voltage Sense wiring.” We incorporated the original busbar, BMS system, contactors, HV connector, fuses, and the entire protective structure with added reinforcement for the bottom and top parts of the battery system.

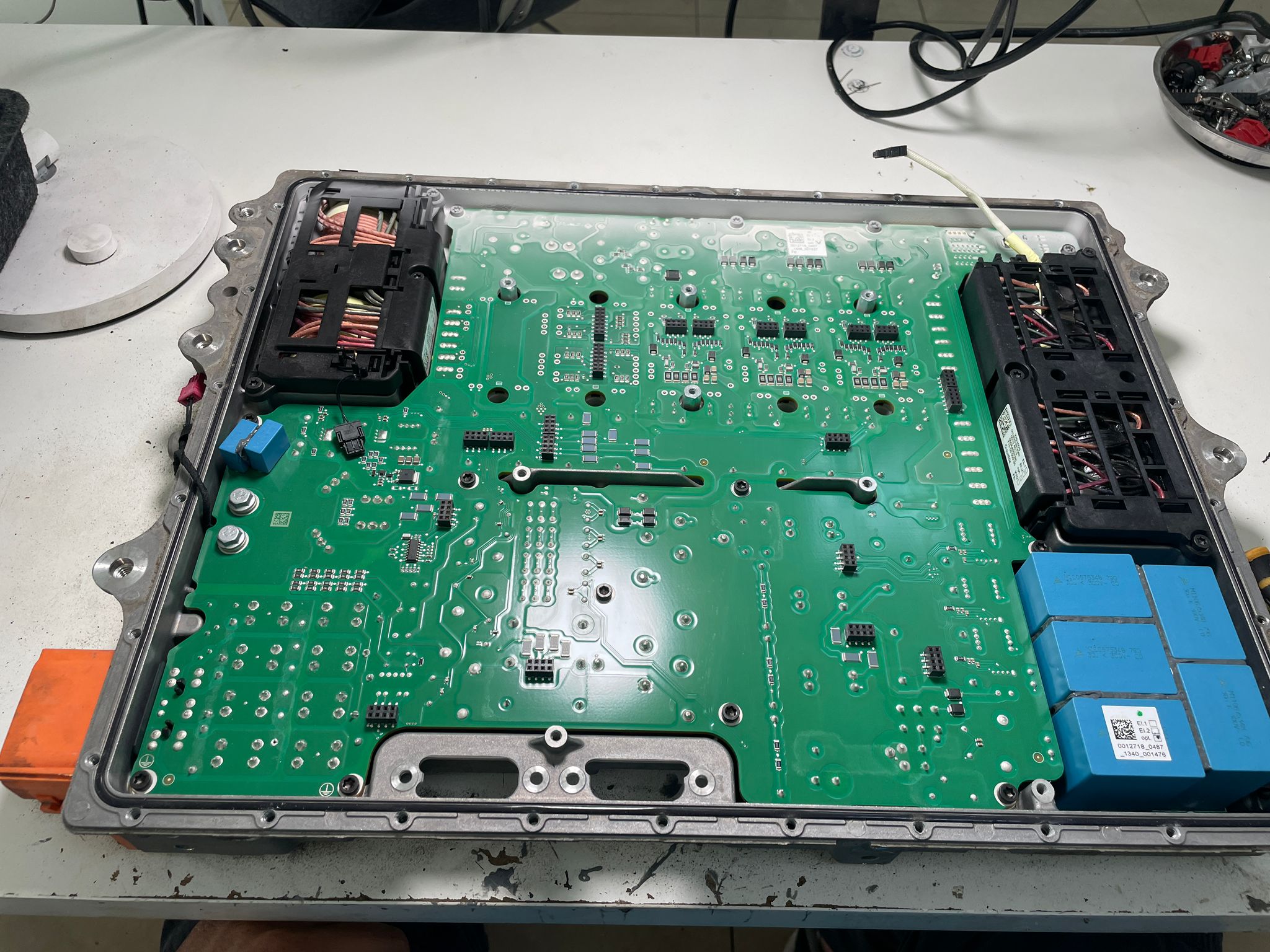

Before assembly, we conducted an OBD test on the table to ensure that we correctly connected all “voltage sense wiring” from Ford cells to the CSE slave balance board controllers.

Now, the most crucial part: the battery that served as a donor for this project had around 50 damaged cells and was deemed a total loss since the number of cells for replacement exceeded the vehicle’s value. The remaining functional cells were tested and recycled for the restoration of 3 vehicles from Croatia, each having about 10 damaged cells. Thus, we maintained a sustainability loop without the unsustainable cannibalization of another vehicle.

Now, some statistics, estimated prices, and our future plan. First: This battery reduced the vehicle’s weight by 50 kilograms, which will inherently reduce consumption and extend range. Second: It reduced the internal cell resistance from the old 1.1 mOhm to a new 0.98 mOhm, while the DCir was lowered from 3 mOhm to 1.2mOhm. This result is the holy grail of the entire project, as this reduces battery heating, thermal losses under load, and charging losses, all of which add a performance and range bonus. Third: Cell cooling is more efficient because it cools with a larger contact surface than before, where previously only copper bridges were cooled after battery terminals and small welds on connections. Fourth: We didn’t design the battery just to make it and then be unable to repair it ourselves or by a third party. The sustainability of any automotive product is based not on how expensive it is to fix, but on how simple it is to repair and replace a part. We configured blocks in the original casing with CSE wiring such that a few screws and some connector unhooking will easily replace the block. You don’t need an astronaut to fix the system as you would with a Hybrid or Hydrogen nonsense.

The system’s price will be between 6000 and 8000€ including VAT, where you leave your old unopened battery for exchange and receive a tested EVC battery. We’ll streamline the process to 3 work hours for battery service. Your old battery goes for EVC reincarnation, and the old cells are used to rescue other vehicles on the road, permanently halting cannibalization. Considering that the MB service asks for 14000e for another used battery and allegedly 28000e for a new one, this is more than an acceptable price for a far better, longer-lasting, and higher quality solution.

And now, the most important question is, “how many ‘million kilometers on a single tank with a catheter connected to the pee pipe’ does it go?” The range that, in practice, with a 10-year-old battery and somewhat healthy cells was around 90km in summer, and 60 in winter, we have raised it to a realistic 140 km range in summer at moderate temperature. We will test the winter range as it had the most significant losses due to the increased internal resistance of the cells at lower temperatures. This is a project I did for myself and my vehicle, so the effort invested in details is primarily focused on meeting my high demands for quality and sustainability. Driven by the goal to make it better than the original and to have a sustainable solution in the entire circular economy. I have closed that circle; it’s up to you to continue it with me.

And in conclusion, a point we’ve emphasized several times is that the European automotive industry is highly deceptive and unsustainable. They manufacture vehicles without providing a sustainable solution for sourcing/producing replacement parts, integrate programmed faults, and limit access to service information. Promoting eMobility as sustainable while selling unsustainable products is akin to the Dieselgate scandal, just dressed in silk.

Rest assured, EVC won’t let that slip under the radar.

HRVATSKI

PROJEKT “VALHALA”

Ovo je bila misija od 3 mjeseca, misija personalne prirode, misija u kojoj je bio cilj da najdraži i najkvalitetniji mali gradski EV spasimo od globalne kanibalizacije za dijelove. Smart 451ED kojeg je prvo Tesla napravila sa svojim pogonskim sustavom rane 2008/09 za Daimler, kasnije ih je radio sam Daimler sa BOSCH pogonskim sustavom SMG180 elektromotorom , BOSCH AccuMotive i “made in germany” LiTec pouch 50Ah celijama koje su u to vrijeme bile poprilično visoko tehnološko postignuće. Medjutim prošlo je 10 godina i za ta vozila nigdje nije moguće kupiti adekvatne zamjenske ćelije. Ovo je i priča o primjeru neodrživosti automobilske industirije koja ne nudi dugoročno riješenje za zamjenske pa čak i “component level” dijelove, jer ovaj Smart 451ED kronično boluje od nedostatka dijelova, najviše za baterijski sustav. Baterijski sustav osim što ima intergrirane programirane greške BMS-a kako bi vlasnika bankrotiralo, također je i dugorocni problem degradacije rubnih ćelija, koje i pored aktivnog hladjenja i grijanja baterije antifrizom dolazi do kristalizacija elektrolita i oštećenja samih slojeva ćelije. Kao što je prikazano na donjoj slici gdje je rub ćelije kristalizirao, uzdigao se i počeo rezati slojeve susjedne ćelije.

Jedan degradirani battery pack ima od prilike oko 12 ćelija za izmjenu kako bi se vratilo u obim 90% zdravlja baterije. To je moguće samo ako imaš materijal na stanju i tu nastaje problem, jer materijala nema. Jedini materijal koji se moze dobiti je kanibaliziranjem jednog elektricnog 451ED kako bi popravio 4-8 vozila, naravno ako je samo 10ak celija za izmjenu. Medjutim u praksi je priča još žalosnija jer imali smo primjere gdje je bilo oštećeno i 80 od 93 ćelije, što je ujedno i totalna šteta.

Ali zato smo mi mjesecima kovali plan i došli do riješenja. Riješenje koji je naišlo sasvim slučajno u obliku reciklirani ćelija iz Ford Hybrida, ford hybrid je zavrsio na smeću gdje je svakom hyridu i mjesto a mi smo ćelije iskoristili u dizjaniranje kompletno novog baterijskog sklopa sa “block to pack” homologiranim i atestiranim sustavom koji je imao već intergriran voltage sense PCB konektor, čelično kućište, izolaciju, stress i drop test i ono najbitnije, state of the art Samsung SDI Prismatic ćelijema sa 6C discharge rate i 50Ah kapaciteta koje u potpunosti kapacitetom odgovaraju starom dizajnom, ali sa jedni velikim poboljšanjem hlađenja tijela ćelije i ono najvažnije smanjenjm ukupne mase baterije za 50 kilograma zadržavajuci isti originalni kapacitet baterije.

Tako smo matematikom , mjerenjem dimenzija i prije samog početka projekta došli do zaključka da je ovo jedino adekvatno i sigurno riješenje za reinkarnaciju Smart 451ED. Ujedno i riješenje da Hybrid kao najveći promašaj autoindustrije ipak ima neku plemenitiju i korisniju svrhu od trošenja resursa na placebo “uštedu” i “jeftinije kretanje”.

Projekat je ovako počeo:

A na kraju je ovako završio i uspješno proradio od prvi put:

U kompletnom procesu reciklirali smo apsolutno sve. Koristili smo original zaštitni kavez od aluminija koji je bio rubni štit i nosač za original ćelije, korišteni su original “coolante plate” hladnjaci, originalno ožičenje i 451 baterije i original ožičenje Ford bloka sa “Voltage Sense wiring”. Original busbar, BMS sustav, kontakotri, HV konektor, osigurači i kompletna zaštitna konstrukcija sa dodanim ojačanjem donjeg i gornjed dijela baterijskog sustava.

Prije samo sastavljanja napravili smo OBD test na stolu da potvrdimo da smo spojili pravilno sve “voltage sense wiring” sa Ford ćelija na CSE slave balance board kontrolere.

A sada ono najbitnije, baterija koja je bila donor ovom projektu imala je oko 50 oštećenih ćelija i baterija je progašena totalnom štetom jer broj ćelija za izmjenu prelazi vrijednost vozila. Ostatak ispravnih ćelija smo ispitali i reciklirali za resturacija 3 vozila iz Hrvatske koji su imali po 10 oštećenih ćelija. Tako da smo krug održivosti zadržali bez neodržive kanibalizacije drugog vozila.

A sad malo statistike, okvirne cijene i koji nam je plan za dalje.

Prvo:Ova baterija spustila je masu vozila za 50 kilograma što će samo po sebu smanjiti potrošnju i povecati domet, Drugo: Smanjila je unutarnji otpor ćelije sa starih 1.1 mOhm na nove od 0.98 mOhm, dok je DCir smanjen sa 3 mOhm na 1.2mOhm. Taj rezulat je sveti gral cijelog projekta jer ovim smanjujemo grijanje baterije i termalne gubitke pod opterećenjima i gubitke na punjenju što paralelno dodaje plus na performanse i domet.

Treće: Hladjenje celija je efektivnije jer se hladi vecom dodirnom površinom nego prije, gdje je prije hladilo samo bakarne mostove poslje baterijskih terminala i malih varova na spojevima.

Četvrto: Bateriju nismo osmislili da je napravimo a da je ne možemo mi ili neko treći popraviti. Održivost bilo kojeg automotiv proizvoda temelji se na činjenici ne koliko je skup za popraviti, već koliko je jednostavan za popraviti i zamjeniti dio. Blokove smo konfigurali i originalnom kućištu zajedno sa CSE wiringom tako da je odvijanjem par vijaka i odpajanjem konekotra blok vani i jednostavno ga zamjenite. Ne treba vam astronaut da vam popravi sustav kao na Hybridu ili Hydrogen budalaštini.

Cijena sustava ce biti izmedju 6000 i 8000€ sa PDV, gdje vi ostavljate svoju staru neotvaranu bateriju na razmjenu a dobijate EVC bateriju testiranu. Proces ćemo svesti na 3 radna sata za servis baterije. Vaša stara baterija ide na EVC reinkarnaciju a stare ćelije idu za spašavanje drugih vozila na cesti tako da ćemo kanibalizaciju trajno zaustaviti.

S obzirom da MB servis trazi 14000e za drugu rabljenu bateriju i navodno 28000e za novu, ovo je i vise nego prihvatljiva cijena za daleko bolje, dugotrajnije i kvalitetnije rijesenje.

A sada ono najbitnije pitanje je, koliko to ide “milijuna kilometara sa jednom rezervarom i spojenim kateterom na pipi”. Domet koje je u praksi sa 10g starom baterijom i koliko toliko zdravim celijama bio oko 90km ljeti, i 60 zimi, mi smo ga digli na realnih 140 km dometa ljeti na umjerenoj temperaturi. Domet zimi tek budemo testirali jer tu je imao najvece gubitke zbog porasta unutarnjeg otpora celija na nizim temperaturama. Ovo je projekat koji sam radio sebi za svoje vozilo, tako da ulozeni trud u detalje je primarno fokusiran da zadovolji moje visoke zathjeve kvalitete i održivosti. Vodjen ciljem da se napravi bolje nego je original i da je riješenje održivo u kompletnoj kružnoj ekonomiji. Ja sa taj krug zatvorio, na vama je da ga skupa nastavimo.

I na kraju kompletan zakljucak koji vec nekoliko puta naglasavamo je da je europska autoindustrija izrazito obmanjujuca i neodrziva, proizvode vozila za koje nemaju odrzivo rijesenje nabave/proizvodnje zamjenskih dijelova, integriraju programirane kvarove i limitiraju pristup servisnim infomarmacijama. Put kojim promoviraju eMobility kao odrziv a prodaju neodrzive prozivode je isto što i dizelgate afera, samo u svilenom ruhu.

Used OEM battery: 14000 Euro

NEW OEM battery: 28000 Euro

EVC NEW battery: 8000 Euro