********** IT IS PROHIBITED TO COPY CONTENT WITHOUT THE APPROVAL OF EV CLINIC **********

Is every EV good? Are hybrids really that bad? This is a topic we’ve been seriously considering for a while due to the frequent questions we receive. It is complex and demanding, requiring thorough experience and extensive information both inside and outside our laboratory. We will update this article periodically in the event of positive or negative changes, and it will be based solely on real experiences and events, without the influence of sponsors or media. Over the past five years of transitioning to EVs, as both a user and a mechanic who repairs them, we will list which vehicles should be avoided, which ones are reliable, the mileage at which issues arise, repair and part costs, and whether they are truly sustainable.

The battery system, as the most important part of any EV, is often the most expensive component. In most cases, it can be repaired, but there is a calendar and mileage age, i.e., battery wear, that occurs at a certain point when battery degradation exceeds 50%, leading to technical failure and necessitating the replacement of the entire battery or all cells if it makes economic sense. In many cases, the dimensions of the original cells do not have commercially available replacements, so replacing individual cells is not possible, and a new or used battery system must be purchased.

Based on our experience and that of our colleagues’ labs at 15-20 different locations worldwide, we have concluded that the battery is the last concern on the list during the first 10 years of an EV’s life, with some vehicles covering a large number of miles with the original battery system. The most common failures within 10 years of using an EV are: 1. Electric motors, 2. OBC chargers, 3. DCDC/inverters, and only in fourth place, batteries. Some vehicles can go 10 years without any breakdowns or servicing, resulting in significant savings compared to fossil fuel vehicles. Even EVs that experience faults are cheaper to maintain than their fossil-fueled counterparts, even when factoring in battery and motor failures. Fossil fuel vehicles consume at least €0.13 per kilometer just in fuel, excluding services and breakdowns. With services, breakdowns, and maintenance, they consume an additional minimum of €0.08, totaling over €40,000 for 200,000 km. Thus, a faulty EV is still cheaper than a “functional” fossil fuel vehicle.

It is important for all current and future owners to understand that battery systems go through multiple cycles during “battery repairs.” The first cycle lasts while the battery is new, typically 5-8 years until the first failure, during which modules or defective cells are replaced. After that, a cycle of battery servicing occurs every 2-3 years (extending the lifespan), which is cheaper as it usually involves repairing individual cells or other components within the battery system. It is crucial to understand that a battery that has lasted 8 years and 200,000 km cannot be restored for another 8 years and 200,000 km. Depending on the model, sustainable repairs address faulty components and extend the lifespan by an additional 2-3 years or 100,000 km. Electric motors, on the other hand, have a lifecycle defined by a certain number of kilometers, after which they are restored and can then be driven for the same or more kilometers again. POUCH cells are the most prone to failure and are often irreparable. The easiest to repair and longest-lasting cells are CYLINDRICAL cells, followed by PRISMATIC cells as the most reliable.

Hybrid systems, due to their large systems on small batteries, often deplete their charge/discharge cycles, with higher amperages running through a small system that is constantly overburdened. Often, by 100,000 km, the battery needs to be replaced. Owners of these vehicles hope for the usual myth called “battery regeneration,” which does not exist. Once the cells are damaged, there is no procedure to save the battery except to replace all cells, i.e., the entire battery. Hybrid vehicle batteries are often the most expensive, sometimes even more so than EV batteries. Considering that a new hybrid battery costs on average between €12,000 and €20,000, and it typically needs replacement after 100,000 km, the cost of electric driving comes out to around €17 per 100 km. As Facebook experts would say: “enough said.” Now, let’s move on to the list of vehicles.

BEST USED EV LIST:

TESLA S 3 X & Y models

Tesla, which mainstream media often attacks with fabricated information and disinformation, continues to remain silent while producing the best drivetrains in the world that renowned car manufacturers are only now attempting to replicate. However, not every Tesla is always recommended. Prices vary from €8,000 to €40,000. The Model S and Model X use battery systems with 18650 Panasonic cylindrical cells, while the Model 3 and Model Y, depending on the type of battery, use cylindrical 2170 and prismatic cells (LFP or Blade).

Our practice has shown that repairing battery systems with cylindrical cells is feasible and easier, even more so in the Model 3 than in the Model S, contrary to previous beliefs. The batteries have proven to be very reliable and long-lasting, with one drawback: preventative sealing is needed for the Model S and Model X to prevent water ingress. The Model 3 and Model Y do not have this issue, and sealing is unnecessary as they only have two umbrella valves for air venting, while the Model S and Model X have 86 valves.

The early-generation Model S with rear-wheel drive or 4×4 Performance uses the rear motor coded as LDU (Large Drive Unit), which is still one of the best induction motors ever designed. However, it has a significant flaw in the rotor cooling design, which can lead to seal damage and coolant leakage into the motor’s interior. Timely addressing this issue is recommended to prevent major motor damage. In addition to restoring them, we improve these motors in at least ten different ways, including a crucial modification that prevents further coolant leakage into the motor’s interior while preserving the original rotor cooling design. This is extremely important as cooling also helps maintain the bearings, which could otherwise be damaged after 50,000 km without adequate cooling (as seen in vehicles such as Kia, Hyundai, Zoe, Twingo, Smart, etc.).

Tesla is also the only electric vehicle that can meet all needs, including local commuting and long-distance travel, making the ownership of fossil-fuel or hybrid vehicles completely unnecessary. (Mercedes EQS, Kia EV6, and Lucid Air are also suitable for all uses and ranges.)

Models S and X (75D, 85D, 90D, 100D) are recommended due to their very durable small induction SDU electric motors (Small Drive Unit), which do not use coolant in the rotor for cooling. All motor parts except the rotor are cooled with coolant, while the rotor is cooled with oil. This means they do not have the rotor cooling issues seen in LDU motors, which can be confusing for Tesla buyers. You can be confident that all motors produced after 2015 use the SDU and have a floating rotor bearing for rotora current discharge, cooled with oil and lasting for a significant number of kilometers. Motor whine is normal and may increase with mileage but does not indicate motor failure or require servicing before at least 500,000 km.

However lately we discovered that 100kwh packs have design flaw on sense wiring, but once repaired by us, it can probably drive 500,000 without same issue: https://evclinic.eu/2024/10/18/teslas-100kwh-achilles-heel-uncovered/

Motor failure occurs around 500,000 km:

- New motor: €3,500

- Motor repair: €1,800

- Preventative differential oil change is recommended at 200,000 km.

A simple battery system failure occurs at 200,000 – 300,000 km:

- Repair: €800 – €4,500 (A “simple” failure includes battery resealing and pressure retention testing to prevent water ingress. If the battery is original and has never been replaced under warranty, resealing is needed after 6-7 years or 250,000 km.)

A more expensive failure occurs at 350,000 – 500,000 km:

- New battery: €18,000

- Used battery: €8,000

OBC (on-board charger) failure occurs between 300,000 and 500,000 km:

- New OBC: €2,800

- OBC repair: €1,200

- Used OBC: €1,000

From the failures we have resolved, we recorded 2 battery system failures, approximately 20 charge port failures, 10 PTC heater failures, and 10 cabin PTC heating failures. Models 75D, 90D, and 100D have never had documented malfunctions.

RESEAL is necessary after 8 years on the 2.0 version of the battery system because the Umbrella valves harden, and oxidation on the fuse cover pushes out the seal, allowing water to enter. Example shown in the picture. More in detail: https://evclinic.eu/2024/07/27/maximizing-tesla-s-x-battery-life-the-critical-role-of-resealing/

Models S 60, 70, 75, 85, 90, and all Performance models (PxxD) or rear-wheel drive only are moderately recommended. After 2015, the Performance models use the rear LDU motor and the front SDU motor, which may confuse buyers expecting the LDU motor to be only in older generations. However, the LDU motor was still installed until 2021, but only in models labeled P and 4×4 (P85D, P90D, P100D).

Motor failure occurs approximately every 50,000 – 100,000 km:

- New motor: €7,000

- Motor repair: €3,500 Preventative motor repair is recommended to avoid failures after 300,000 – 500,000 km.

- A simple battery system failure occurs at 150,000 – 250,000 km:

- Repair: €800 – €5,500 More severe failures occur at 250,000 – 400,000 km:

- New battery: €18,000

- Used battery: €8,000

- Battery repair: €5,500, which in rare cases may be unsuccessful.

- OBC (on-board charger) failure occurs from 200,000 to 300,000 km:

- New OBC: €2,800

- OBC repair: €1,200

- Used OBC: €1,000

From the failures we have handled, 200 motor failures, 100 battery failures, and 10 OBC failures have been recorded. The highest documented mileage of a single battery without any service is in a 2014 Model S85 with 598,000 km.

Models 3 and Y SR, LR, and P are recommended due to their highly durable small SDU electric motors.

Motor failure occurs at around 500,000 km:

- New motor: €2,600

- Motor repair: €1,500

- Differential oil change is recommended at 200,000 km.

A simple battery system failure occurs at 100,000 – 300,000 km:

- Repair: €800 – €4,500

More severe failures occur at 350,000 – 500,000 km:

- New battery: €16,000

- Used battery: €7,000

- Battery repair: €4,500

OBC (on-board charger) failure occurs from 300,000 to 500,000 km:

- New OBC: €900

- OBC repair: €800

- Used OBC: €600

From the failures we have resolved, 1 charge port failure and 3 battery system failures have been recorded.

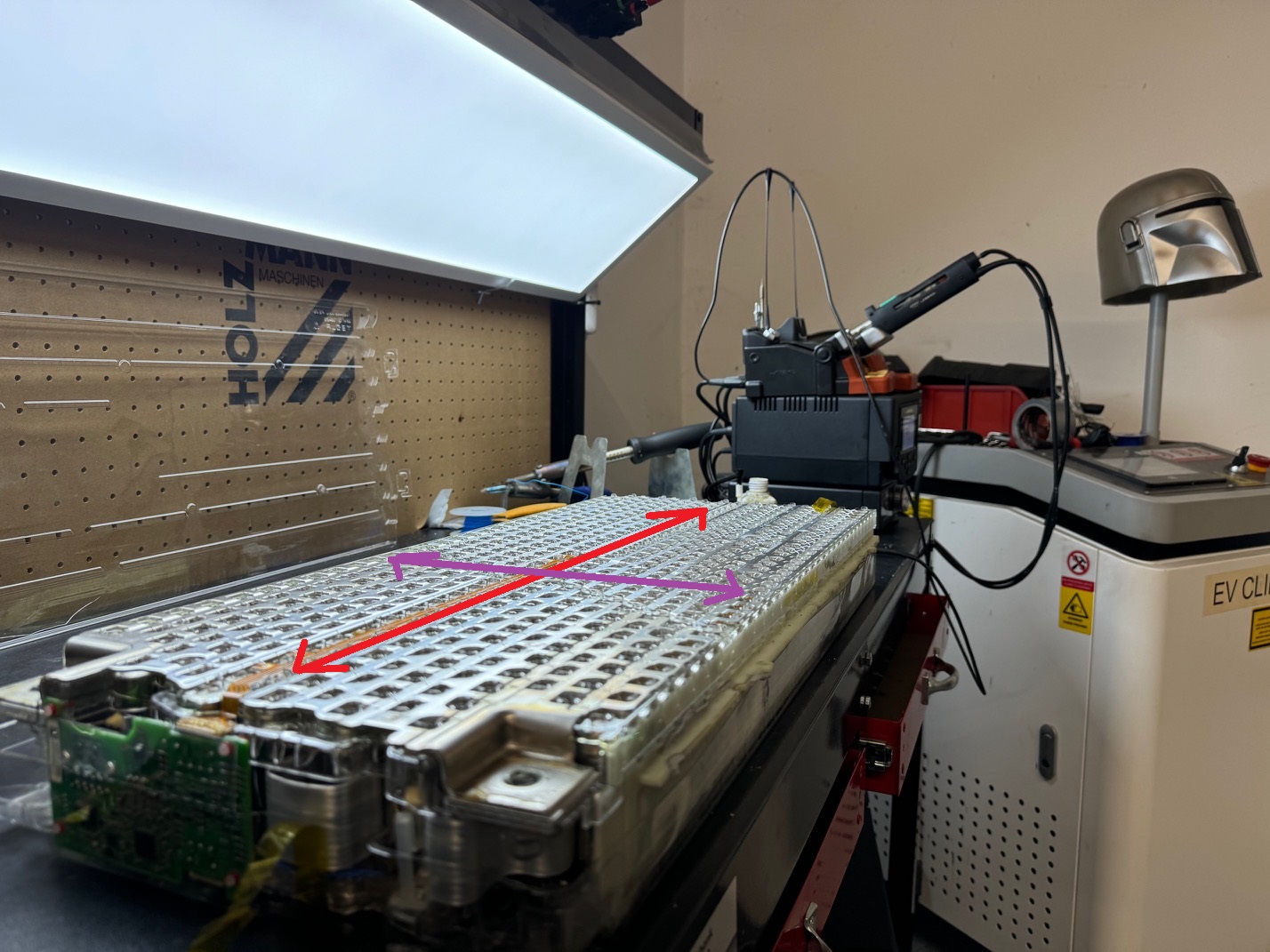

The early samples of the Model 3 SR with NMC cells and a small 45 kWh battery pack have more pronounced issues due to having nearly half as many cells in parallel compared to the LR version. This accelerates system wear and can damage one or more cells, causing the entire parallel group to discharge. Documented failures occur around 150,000 – 250,000 km in the battery system. Replacement of a single cell is possible. You can see an example in this YouTube video.

When searching for a vehicle and verifying it, it is best to check the VIN with an authorized service center. They cannot provide a printout, but the owner can. The most important thing is to determine whether the vehicle is marked as SUPPORTED or UNSUPPORTED. “Unsupported” may indicate tampering with the vehicle, import from the USA, or a vehicle involved in a major accident, leading to the permanent deactivation of SUPERCHARGER access, a permanent ban on service visits, and the removal of all warranties.

A definitive deal-breaker is a vehicle imported from the USA without an EU charging port; the app and autopilot will not function.

Statistically, the most problematic models are the Model S P85 and P85D. Highly worn-out batteries have been recorded in the P85D and P90D models, along with issues with the rear motor. The most problematic battery systems are those marked 85, although it should be noted that these vehicles often have high mileage.

Realistic ranges:

90D (400V battery): Over 340 km

New Model S – LR and Plaid: Over 450 km

S100, S100D, P100D: From 350 – 480 km

75D: From 250 – 350 km

85 and 85D: Around 280 – 300 km

90D (350V battery): Over 400 km

More in detail: https://evclinic.eu/2023/12/30/which-tesla-to-buy-a-beginners-guide/

SUSTAINABLE: ULTRA (Parts, Right to repair, Documentation, Diagnostic)

LUCID

This is likely one of the best engineering feats, potentially even surpassing Tesla. We have analyzed the development of both the battery and the motor, and we had the opportunity to test drive one in the Netherlands. The motor boasts high power with a planetary gearbox, and the battery is modularly designed and appears very serviceable. They use the best technology available today—cylindrical 2170 cells. This is the only vehicle we would prefer as an official fleet car instead of a Tesla, but its price is quite high.

We are particularly interested in how serviceable the motor is, including details about the bearings and other consumable parts, as well as their availability. Our goal is to acquire one as soon as possible, even if it’s non-functional, because we believe this is the most enigmatic EV—a marketing “sleeper” that deserves more attention.

Overal: WE WOULD BUY IT

SUSTAINABLE: Unknown(Parts, Right to repair, Documentation, Diagnostic)

Hyundai Ioniq 28kWh

The first-generation Hyundai Ioniq is the only vehicle on which we have not had any type of intervention. Several acquaintances who own and drive them report absolutely no issues, and we have no cases in our laboratory. Prices range from €10,000 to €16,000. The battery system is composed of LGX POUCH cells, which have proven to be durable and high-quality.

Expected motor failure:

Around 200,000 km

New motor: €9,500

Motor repair: €1,400

Preventative differential oil change is recommended.

OBC (on-board charger) – no documented failure.

Battery:

No documented failure

New battery: approximately €22,000

Realistic range: 180 – 220 km

SUSTAINABLE: MEDIUM (Parts, Right to repair, Documentation, Diagnostic)

Expensive powertrain parts

VW eGolf

It is difficult to immediately assess the Golf as a good choice, primarily because it is a Golf, then a VW, and finally an electric vehicle. However, it lacks an EGR, DPF, ADDBLUE, injectors, belts, oil or water pumps, clutch, flywheel, gearbox, and many other potential issues, which is a complete contrast to previous versions, especially the Golf 2 1.6D. This model, unlike its predecessors, is very reliable. The first generation has a smaller 24 kWh SYE battery system with prismatic cells, while the second generation has a larger 38 kWh Samsung SDI battery system. Additionally, the electric motors differ between the two generations.

Recorded failures include: three motor failures, one charging port issue, and one battery issue. Vehicle prices range between €8,000 and €14,000.

The expected motor failure occurs around 200,000 km:

NEW: €9,000

REPAIR: €1,400

USED: €1,000

Preventive differential oil replacement is recommended every 50,000 km.

OBC (on-board charger):

REPAIR: €800

NEW: €4,000

USED: €500

Simple battery system failures can be expected between 150,000 and 250,000 km, with repair costs ranging from €800 to €2,500. More severe failures occur between 250,000 and 500,000 km:

NEW: €38,000

USED: €5,000

At high mileage, due to cell aging, increased internal resistance, cell swelling, or possible insulation breakdown, it may be necessary to replace all cells or the entire battery system. The terminals are connected with three cells in parallel and are very difficult to weld with a laser. We plan to develop a solution for replacing all cells, but the project and production will not be cheap, likely exceeding €10,000.

Realistic range:

38 kWh: 150-250 km

24 kWh: 80-150 km

SUSTAINABLE: MEDIUM(Parts, Right to repair, Documentation, Diagnostic)

Expensive powertrain parts

VW eU – Škoda Citigo e iV

A small city car with cobwebs around the engine compartment because no one ever needs to go there. An EV that many car-sharing systems included in their fleets due to its exceptional reliability. The vehicle has only been to the service center twice – once due to the OBC (damaged by a lightning strike) and the second time for a charging error caused by a faulty gear selector that didn’t recognize the “P” position, preventing charging. Before winter, after 5-6 years, it’s necessary to replace the small 12V battery, ensuring trouble-free use thereafter.

The main drawback of the eUp with the small 18 kWh battery (prismatic cells) is a significant range drop in winter due to the lack of thermal control or battery heating. Vehicle prices range from €8,000 to €15,000, depending on the battery size.

Expected failures:

Electric motor: around 200,000 km

NEW: €9,000

REPAIR: €1,400

Preventive differential oil change is recommended every 50,000 km.

OBC:

REPAIR: €800

NEW: €4,000

USED: €500

Simple battery system failures occur between 100,000 and 180,000 km, with repair costs from €400 to €2,500.

More expensive battery system failures occur between 180,000 and 300,000 km:

NEW: €32,000

USED: €5,000

Gear selector:

NEW: €800

At high mileage and vehicle age, due to increased internal cell resistance, swelling, or possible insulation breakdown, it may be necessary to replace all cells or the entire battery system. The terminals are connected with two cells in parallel and are very difficult to laser weld. In several cases where the vehicle would cut off or refuse to charge, it was found that the 12V battery was faulty, so it should be replaced preventatively every two years. This vehicle comes highly recommended.

Realistic range:

36 kWh: 200-250 km

18 kWh: 80-150 km

SUSTAINABLE: MEDIUM(Parts, Right to repair, Documentation, Diagnostic)

Expensive powertrain parts

BMW i3

One of the best small city cars ever made, featuring a perfectly designed motor but lacking rotor cooling, which means that rotor bearings are expected to fail earlier. So far, this has only occurred in one vehicle in our service center with 180,000 km on the clock. The only issue is that the motor is designed to be non-repairable, as explained in the link: https://evclinic.eu/2024/10/27/huston-we-have-a-problem-with-bmw-i3/

The battery is actively cooled and heated with a thermal protection system, using prismatic cells. Although BMW has produced problematic diesel and petrol engines in recent years—prone to fires due to several design flaws (EGR, DPF, timing chain)—it still stands out as the leader in electric vehicles within the European automotive industry, if not the only hope for e-mobility in Europe. We dare say they are even ahead of the Porsche team. Among all European manufacturers, BMW offers the most affordable parts for electric vehicles, the most detailed repair procedures, and highly trained teams of technicians capable of component-level repairs. This means they approach battery repairs locally by replacing modules or other components rather than replacing the entire battery for minor issues.

Vehicle prices range from €9,000 to €20,000, depending on the equipment and battery system.

Expected failures:

Electric motor: around 200,000 km

NEW: €4,800

REPAIR: not possible €

Preventive differential oil change is recommended every 100,000 km.

PTC battery heater

More costly failures occur between 200,000 and 300,000 km:

NEW battery: €32,000

USED: €6,000

Air conditioning compressor (occasionally):

NEW: €1,200

In the past five years, we have serviced only two vehicles – one for a motor mount and the other for an electric motor failure at 180,000 km, which we will write about soon.

If motor whine occurs, it is advisable to perform a preventive repair because if the rotor bearing cage breaks, it can damage the rotor, stator, and resolver.

REX models are extremely reliable and probably the only hybrid we can recommend.

Realistic range:

120Ah: 250 km

60Ah: 80-100 km

94Ah: 130-200 km

SUSTAINABLE: HIGH (Parts, Right to repair, Documentation, Diagnostic)

Component level repair – Battery

Citreon C0, Peugeot iON, Mitsubishi i-MIEV

A pioneer of the EV revolution, which occasionally visits our laboratory, can be confidently categorized as the most reliable veteran. The motors, even after 12 years, have not experienced failures, at least not in the vehicles that have come to us. We have had only 2-3 inquiries related to battery degradation. We worked on one battery system that did not have defective cells but had an issue with the BMS, which we successfully resolved for the client. The most common issue we encountered (5-6 times) was the OBC charger. The original costs over €8,000, and used ones are almost impossible to find. The battery system uses unconventional prismatic NMC cells for which no replacement cells with the same dimensions are available. Prices range from €4,000 to €6,000.

Expected failures:

Electric motor: UNKNOWN

Preventive differential oil change is recommended every 100,000 km.

More costly failures occur at 150,000-200,000 km, along with battery degradation.

The air conditioning compressor occasionally fails (2 inquiries).

The OBC charger fails every 50,000-100,000 km.

REPAIR: €1,200

NEW: €8,000

When purchasing this vehicle, a test drive is recommended to check the range, as well as testing TYPE1 home and public charging to ensure OBC functionality. The Chademo can still work even if the OBC is faulty.

Realistic range: Around 80-100 km.

SUSTAINABLE: MEDIUM (Parts, Right to repair, Documentation, Diagnostic)

Expensive powertrain parts

FIAT 500e – USA

A small and fast city car, which, through the collaboration of the FCA group, Chrysler, and BOSCH, has become an enduring masterpiece and one of the highest-quality older EV systems. The permanent magnet electric motor, BOSCH SMG 180, is exceptionally reliable, with no reported failures. The battery system, also designed by BOSCH, features active thermal management and cooling with antifreeze. The BMS is also by BOSCH, and almost all components within the battery system are BOSCH-made. The cells are prismatic NMC, of non-standard dimensions, for which there is no aftermarket replacement.

We encountered four vehicles that suffered deep discharge due to prolonged transport in containers from the U.S., resulting in battery system failure. Each of these failures was successfully resolved. Another failure we encountered once was an OBC charger malfunction, which is alarming because new units are no longer available, and used ones are impossible to find. A minor drawback of this vehicle is that it only has a TYPE1 charging port, without fast-charging options like Chademo or CCS.

Vehicle prices range from €6,000 to €12,000.

Expected failures:

Electric motor: UNKNOWN

Preventive differential oil change is recommended every 100,000 km.

More costly battery system failures occur at 200,000-300,000 km, along with battery degradation.

Minor BMS failures may occur between 50,000 and 100,000 km.

REPAIR: €1,400

The OBC fails every 50,000-100,000 km.

REPAIR: €1,200

NEW: €7,000 (no longer supplied)

When purchasing this vehicle, a test drive is recommended to check the range, as well as testing TYPE1 home and public charging to ensure OBC functionality. The battery’s SOH (State of Health) can be checked via diagnostics – if it is below 60%, the battery is in very poor condition.

Realistic range: Around 130-160 km.

SUSTAINABLE: MEDIUM(Parts, Right to repair, Documentation, Diagnostic)

KIA SOUL

The Soul, which may not appeal to many aesthetically until they try it, is one of the few vehicles from that era offering a wealth of features and a very comfortable ride. Spacious and comfortable, it includes a heated steering wheel, ventilated seats, and an excellent infotainment system with CarPlay functionality. The most common issues we encountered were with battery systems. We worked on 5-6 vehicles, while about ten clients decided against repairs due to poor SK Innovative POUCH cells, which degrade quickly. Replacement cells with the same dimensions and characteristics do not exist, making us solely reliant on sourcing used batteries to repair existing systems (cannibalization).

In one case, a vehicle from Serbia had such a severely degraded battery that, despite replacing 30% of the battery system, the issue remained partially unresolved, indicating that a full battery replacement was likely needed. The battery’s SOH (State of Health) can be checked via diagnostics – if it is below 60%, the battery is ready for minor repairs. If the SOH is below 40%, the battery system has suffered significant damage, requiring the replacement of a large number of cells or the entire system. We plan to build a larger battery using a new generation of cells from another EV.

The vehicle is recommended only if the price is good and the battery is in working condition or has minor, repairable degradation. Otherwise, it is advised to avoid it. Vehicle prices range from €6,000 to €16,000, depending on the condition of the battery system. The vehicle is equipped with a Type1 single-phase port and a CHADEMO DC port.

Expected failures:

Electric motor (whining): around 150,000 km

NEW: €9,500

REPAIR: €1,400

Preventive differential oil change is recommended every 100,000 km.

Minor battery system failures occur between 40,000 and 80,000 km:

2-20 cells defective (€1,500-3,500)

More severe battery system failures occur between 80,000 and 150,000 km:

20-50 cells – significant degradation (€3,500-5,500)

OEM New – 28,000€

OBC fails every 50,000-100,000 km:

- REPAIR: €800

- NEW: €4,000

- USED: €1,000

When purchasing this vehicle, it is important to do a test drive to assess the range and check TYPE1 home and public charging to ensure the OBC is functioning correctly.

Realistic range:

With a faulty battery: 50-90 km

Around 130-160 km

SUSTAINABLE: MEDIUM(Parts, Right to repair, Documentation, Diagnostic)

Expensive powertrain parts

Mercedes B-Class W246 Electric drive

Mercedes’ only moment of making an excellent EV, a trend they could have continued but did not seize. During the time Daimler co-owned Tesla, they collaborated on the development of the electric B-Class project. The entire system was sourced from the Tesla Model S 85. Almost all parts match those from Tesla, including the most common failure, the LDU (large drive unit) electric motor, which, like Tesla’s, has an issue with coolant leaking past the rotor seal, potentially damaging the motor. It is necessary, and mandatory, to perform a preventive repair on the motor to permanently improve and protect it from this problem. We have already had three faulty motors in the service. One vehicle had a faulty PTC heater for the battery system, and another had a minor battery system issue, which is based on very similar modules to those in the Tesla S with 18650 cylindrical cells, making it easy to repair.

Vehicle prices range between €8,000 and €15,000, depending on mileage and equipment. Compared to the eGolf, Zoe, or other vehicles, this is probably the best choice if the motor has been preventively improved. If not, a lower vehicle price should be considered.

Expected failures:

- Electric motor (coolant leakage): around 40,000 km

- NEW: €9,500

- REPAIR: €3,500

- Preventive differential oil change every 200,000 km.

- Minor battery system failures occur between 150,000 and 200,000 km (2-20 faulty cells or wiring).

- More severe battery system failures occur after 200,000 km (degradation).

It is possible to check for coolant leakage past the seal preventively by lifting the car and removing the rotor sensor. If there are traces of coolant, the motor needs repair. Temporarily, a drain can be created to let coolant out and prevent motor damage in case of a seal breach.

Realistic range: Around 130-160 km.

SUSTAINABLE: HIGH (Parts, Right to repair, Documentation, Diagnostic)

Renault Fluence

Renault’s pioneer, based on the chassis of a fossil-fueled vehicle, was also the first EV designed for quick battery swaps at a “battery gas station” called “Better Place,” which was tested in Israel (we even met an engineer from that project). We personally drove and used a Fluence from Zagreb. Their prices are very low in listings, but care must be taken to ensure the battery does not show an SOH (State of Health) below 60% during diagnostics. When the SOH reaches 50%, the BMS triggers a permanent error, and the vehicle switches to reserve mode to protect the battery from further overheating due to increased internal resistance. The Pouch cells are similar, if not identical, to those in Nissan Leaf batteries, which have proven to be low quality, even with thermal management. New batteries are not available, and used ones are even rarer. Constructing a new battery with modern cells would cost around €6,000-8,000 for a capacity of about 18 kWh (net).

The motors are very reliable, featuring an externally excited rotor with brushes on the windings. Brush servicing costs around €40-80 in Slovenia at an authorized Renault service center, which is the only certified facility for such work in the region. Croatian authorized services are not certified for this task. We have handled 10-15 cases of worn-out batteries and two vehicles with motor failures. There have also been a few sporadic issues caused by a simple 12V battery failure.

Vehicle prices range from €2,000 to €6,000.

Expected failures:

- Motor or insulation issues: between 50,000 and 150,000 km

- OEM SERVICE: €100

- REPAIR: €800

Battery failuer – NOT REPAIRABLE

Preventive differential oil change is recommended every 100,000 km.

More severe battery system failures occur after 100,000 km, with degradation and an SOH below 50%.

It is recommended to replace the 12V battery preventively before winter. The vehicle is recommended only if the price is low, as a replacement for a fossil-fueled vehicle for shorter local trips, which allows for a quick cost amortization. If battery degraded more than 40%, not advicable to buy it. The vehicle does not have a fast charger and uses an old single-phase Type1 port. It is not advisable for longer trips, as the battery may overheat.

Realistic range: Around 80-120 km.

SUSTAINABLE: MEDIUM(Parts, Right to repair, Documentation, Diagnostic)

DACIA SPRING

The cheapest EV you can buy new is this one, and with subsidies, it is the most affordable EV in Europe. A small city car for which we haven’t received any inquiries about major issues, except for some complaints about a whining or clicking sound from the electric drivetrain during regenerative braking in certain models. The battery system is made by Donfeng Sunwoda, with 27 kWh usable capacity and composed of NMC PRISMATIC cells.

Expected motor failure: Unknown Expected battery system failure: Unknown

A new battery costs approximately €12,000.

Realistic range:

around 150 km

SUSTAINABLE: HIGH (Parts, Right to repair, Documentation, Diagnostic)

Smart 451ED

Mercedes, together with Tesla, made a very good B-Class, but believe it or not, the electric Smart 451ED first generation is their true masterpiece. As enthusiasts of all vehicles, this model stands out in particular because the batteries are “Made in Germany.” It is the last EU EV to use a battery system and Pouch cells designed and produced in the EU by Li-Tec. This small city EV is quiet and almost comfortable, and you can park it anywhere. It differs significantly from its fossil-fueled version, as anyone who has driven both knows how irritating the fossil version can be – from the noise and vibrations of the rear-mounted engine to the unpleasant smell emanating from it. Longer drives in the fossil version can be tiring, while in the EV version, they are much more pleasant, albeit an adventure, as the 100 km range requires frequent charging.

There are two charging versions: a 3.7 kW charger and a 22 kW BRUSA charger, which is expensive and becomes problematic after a certain number of kilometers. With the 22 kW charger, a 400 km trip becomes more manageable, as a 30-minute charge allows you to travel from Zagreb to Krk without issues. Using the air conditioning and heating significantly reduces the range, as the system is not well-optimized.

The most common issues include damaged or degraded batteries, but usually only 5-15 cells, which can be repaired to restore the range to about 90 km. The car is recommended if the battery condition and SOH of the cells are checked. Preventive repairs are possible if a potential issue is detected. Another problem is the 22 kW OBC, which in most cases can be repaired. A third issue is the overlooked air conditioning system, which is problematic even in the fossil version, where the front AC radiator can break and cause a gas leak. The AC often operates at 50% capacity, so while it cools the cabin, it is not sufficient for the battery. If you are unaware of this, you can damage both the battery and the OBC over time. We assume that a partially filled AC system is the most common cause of battery and OBC damage. It is necessary to check for AC leaks and, if needed, disassemble the front end and replace the AC radiator. The motor has never failed.

Expected minor battery failures: 40,000-80,000 km, REPAIR: €800-2,000

Expected major battery failures: 60,000-100,000 km, REPAIR: €2,000-4,000, REBUILD: €6,000,

NEW MERCEDES: €14,000

NEW EVC: 6000€’+tax – https://evclinic.eu/2023/10/13/451ed-battery-reincarnation-and-tuning-hard-to-die/

Preventive differential oil change every 100,000 km

OBC failure every 40,000 km: REPAIR: €1,000, NEW: €7,500

Vehicle prices range from €5,000 to €9,000. Realistically, a better buy than the 453EQ.

It is recommended to replace the 12V battery preventively before winter. The vehicle is highly repairable, highly recommended, and a better option than the newer Smart 453EQ. It is far more robust and durable, and maintenance is cheaper. The downside is that it can be quite stiff on rough roads. When purchasing a faulty vehicle that has been sitting with a discharged battery for a long time, the risk is extremely high, as if the battery has been empty for more than a year, there is a significant chance it is completely damaged (two buyers already had to sell their vehicles for parts at a loss). To determine if the vehicle has fast AC charging (22 kW, Schnellader), open the charging port and check if there are pins in each socket (seven total). If two pins are missing, the vehicle has a single-phase 3.7 kW charger, which takes 6-7 hours for a full charge. A simple test for checking the battery condition is to drive the vehicle below 20% charge – if it shuts off before the gauge reaches 0% or if the charge drops sharply towards 0% during driving, it indicates that one or more cells are weaker than the rest of the battery system.

Realistic range: Around 80-100 km.

SUSTAINABLE: HIGH (Parts, Right to repair, Documentation, Diagnostic)

LOW WARRANTY TIME

Programmed defects

KIA HYUNDAI – 2020 IONIQ NIRO KONA

Although we decided to include only older and more affordable EVs that fit the budget of the general population, we will make an exception for new Korean models that are very reliable and dependable. We can briefly note that we receive very few inquiries about these vehicles – most are thank-you messages from owners who use them for taxi services or personal purposes, stating they have had no issues. The only documented drawback is with the Niro and Kona models, where owners have reported motor whining after relatively low mileage. The cost of a new motor is around €10,000. For some vehicles, the motor started to whine at 50,000 km, while for others, it only occurred at 150,000 km. One owner from Oslo reported an issue with the OBC, and that’s all we have documented so far. We will certainly update this section if we receive additional information.

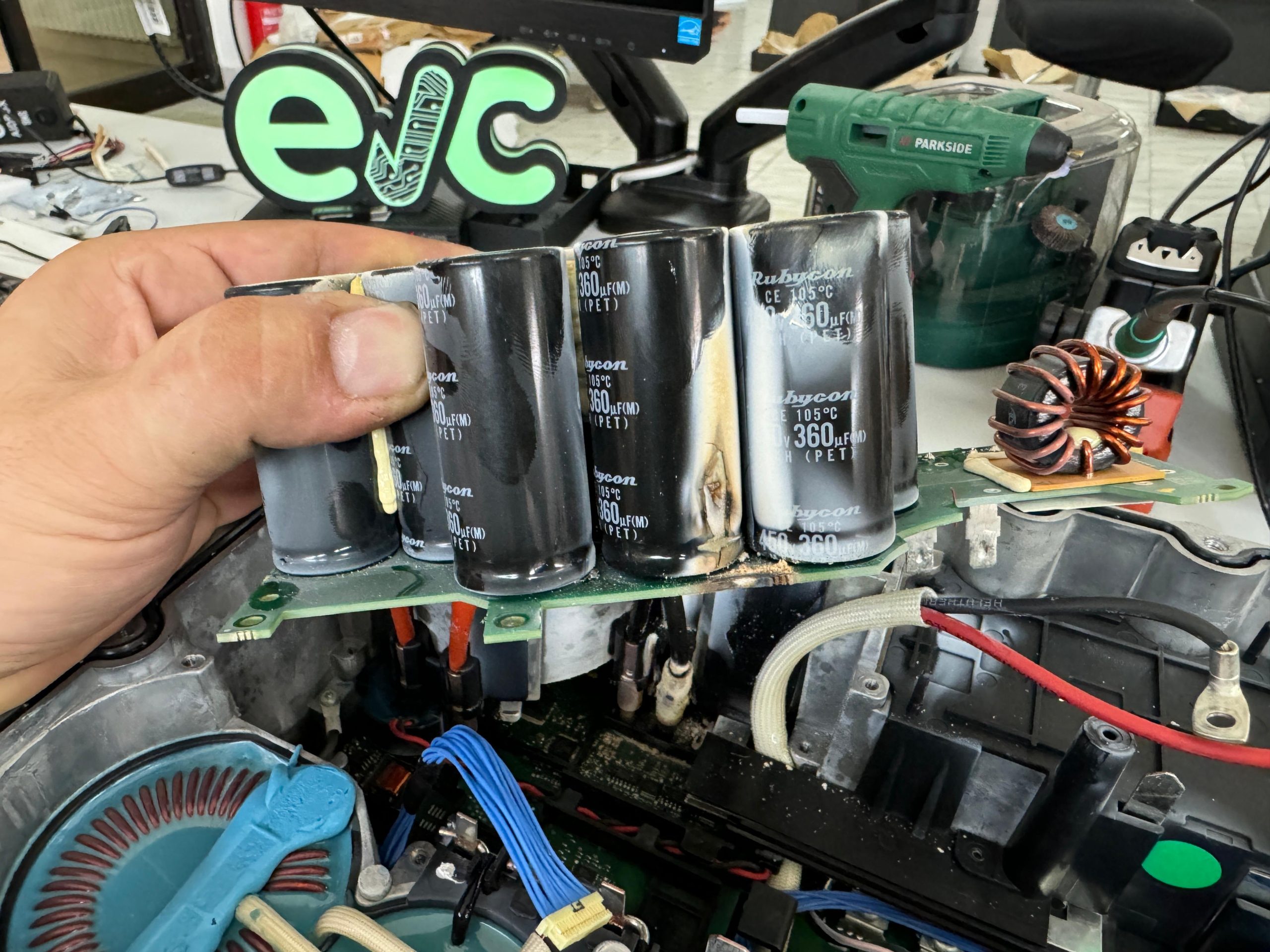

A significant disadvantage of Korean models is the very high cost of new batteries, which exceeds €40,000, a concerning factor. One EV KONA from Zagreb had its battery replaced twice up to 180,000 km under warranty, which could be worrying for owners out of warranty. However, as the saying goes, one swallow does not make a summer, so it is still too early for a final conclusion. In our opinion, the biggest drawback of Korean vehicles is not the motor but the manufacturer’s decision to use Pouch cells in their battery systems. These cells have proven to be a complete failure due to poor performance and very low reliability in electric vehicles. According to our statistics, we have recycled 1,500 kg of completely defective Pouch cells so far, while in the same period, we have only recycled 200 grams of prismatic and cylindrical cells. Most of the recycled Pouch cells came from Kia Soul, Kia hybrids, and the electric Smart.

Expected motor failure (Niro, Kona): 50,000-100,000 km

NEW: €10,000

REPAIR: €1,400

Ranges: ().

SUSTAINABLE: Unknown (Parts, Right to repair, Documentation, Diagnostic)

Fiat 500e 2021>

This time, originally Italian but under Stellantis’ direction, and the only Stellantis model we love and partially approve of. The perfect small city car and the best substitute for all other small urban electric vehicles. Fast – Compact – Agile – Reliable. The Fiat 500e significantly differs from the PSA group in its powertrain, as it uses a unique OBC, inverter, and electric motor system not shared with the rest of Stellantis’ lineup, proving to be highly reliable. The battery is made of Samsung SDI NMC PRISMATIC cells, and the battery system features integrated active thermal management with antifreeze-based heating and cooling. As usual, do not rely on the warranty, as in all cases so far, there has been an excuse for “warranty r-a-p-e,” invalidating it for some reason. We have worked on four vehicles with battery defects, one of which had a battery that locked and deactivated for replacement due to an unknown reason—a deliberately implemented safety feature that activated unnecessarily, forcing owners to replace a functional battery, an unsustainable absurdity. However, with our solution development, we found a software switch to deactivate the error, allowing the battery to function again, and some vehicles have been on the road for two years since.

Example of one case: Fiat 500e battery defect – Stellantis warranty issue

Example second case of warranty abuse and unsustainable aftermarket support and policy: https://evclinic.eu/2024/11/03/if-you-drive-a-stellantis-vehicle-may-god-help-you-part-3/

Motor failure – not documented

Battery system failure – documented programmed failure – mileage from 5,000-50,000 km – NEW: €14,000 – REPAIR: €1,600

This vehicle is recommended because it is irreplaceable for the fun it offers and has the most desirable battery system, which is quite large for such a small vehicle. It features fast CCS charging and active thermal management. The battery issue is solvable, and there has never been a documented case of cell failure, making the software-programmed fault we can fix definitely not a “deal breaker.” We are even exploring the potential that the fault may be triggered by a poor battery causing a “voltage hardware glitch.” We dare say this is a better small EV than the entire German and French lineup.

Realistic range:

24 kWh: 150 km

42 kWh: 250 km

SUSTAINABLE: LOW (Parts, Right to repair, Documentation, Diagnostic)

Expensive powertrain parts

Circular economy 0

Right to repair access (tools and documentation) 0

VAG – 2020> VW AUDI SEAT SKODA PORSCHE

The new generation of VAG electric vehicles deserves at least a mention, even though we avoid commenting on models that are not within our range of services since they are still relatively new. However, here’s what we do know. The most common inquiries we receive are related to the battery system following an accident, where, due to the pyrotechnics in the battery, it is necessary to remove the battery system, open it, and replace the pyro, which costs around €1,000 new. The procedure is not very demanding, but the new pyro requires online programming with the ODIS system.

Given that these vehicles are still young on the road and we receive very few repair inquiries, it indicates that VAG respects owner rights and warranties, unlike “warranty rape” manufacturers such as Kia, Hyundai, Stellantis, and Mercedes. Their battery systems are exclusively based on Pouch cells, and there is evidence of VINs leaked publicly showing that around 20,000 vehicles were recalled due to battery system defects. Some owners report that their batteries were repaired under warranty with module replacements 1-2 times. To quote: “My ID.3, 2021, has 65,000 km, and battery modules were replaced twice under warranty. Otherwise, I’m very satisfied with the vehicle.”

Additionally, their infotainment systems have been notably poor, consistent with the entire VAG lineup over the past 20 years.

We have never received inquiries for motor repairs.

Among all the vehicles offered, the Audi e-Tron 55, Audi e-Tron GT RS, and Porsche Taycan are well-built and high-quality models.

From reliable sources, we know that Porsche’s 800V systems have experienced insulation problems, but unfortunately, we haven’t worked on one yet, so we don’t know the exact cause.

SUSTAINABLE: HIGH (Parts, Right to repair, Documentation, Diagnostic)

Component level repair – Battery

Renault ZOE Q210 – 2013 -2016

A car we don’t particularly like, but it’s the only vehicle whose battery has never failed, and it’s incredibly reliable. Believe it or not, no battery system has ever come in for service. The first-generation electric motors marked with a Q, produced by Continental with externally excited rotors via windings, are extremely reliable and efficient. The most common issue we’ve encountered is with the OBC BCB charger, which is very sensitive and almost an unfinished semi-product. You can have the OBC serviced at an authorized service center or with us, with a slight price difference – it’s a bit cheaper with us, ranging from €800 to €1,000. The motors are highly reliable and, along with the eGolf, are the only motors that can last up to 200,000 km. Regular differential oil changes are recommended to prevent complete gear damage due to bearing cage failure. If you hear a whining sound, it’s necessary to preemptively restore the entire motor and gearbox – better to prevent than to replace. Used motors are almost impossible to find, and new ones cost over €4,500. The battery system uses Pouch cells. Vehicle prices range from €6,000 to €14,000, depending on the model and battery condition.

Expected minor battery failure – not documented Expected major battery failure – not documented Expected motor failure – 150,000-200,000 km

REPAIR: €1,200

NEW: €4,500

Preventive differential oil change every 100,000 km. OBC failure every 80,000 km:

REPAIR: €1,000

OEM: €900-1,500

It is recommended to replace the 12V battery preventively before winter, as the vehicle is sensitive to small battery degradation, which can cause alarming errors related to the battery and motor. The vehicle is very repairable, far more robust and durable than the newer R240 model. A major advantage is that a 22 kWh battery model can be easily upgraded to a 40 kWh battery (plug & play). The vehicle only has AC Type 2 charging, without fast CCS. When purchasing, check if the air conditioning works and how noisy the compressor is, as a new one is very expensive, over €2,000. Also, at a public charging station, verify if the vehicle charges at 22 kW and leave it to fully charge. If charging interruptions occur, it could indicate an issue with the OBC or another cooling system component.

Realistic range:

40 kWh: around 200 km

22 kWh: around 80-100 km

SUSTAINABLE: HIGH (Parts, Right to repair, Documentation, Diagnostic)

Renault ZOE, Twingo R240 – 2016 -2022

This vehicle is even less favored by us due to its higher number of failures and general unreliability, but we will be objective as we know many owners who are extremely satisfied with its ergonomics and compact design. The car performs excellently both in city conditions and on longer journeys. The rear-wheel drive system (RWD) is designed with the motor mounted inside an L-shaped aluminum housing, secured along with the motor itself. In the event of any failure, the front subframe must be removed (unlike the Twingo), the axles disassembled, and the motor removed to replace the faulty part. This is followed by reassembly and testing, which can take several hours just to verify if the repair was successful. For this reason, it is sometimes more cost-effective to buy a new part, install it, and complete the repair in one step, as each repeated repair takes 1-2 working days, potentially resulting in higher costs than purchasing a new part.

We partially recommend this vehicle but with the note that you must be prepared for unforeseen expenses up to €2,000, which even we cannot predict or prevent. The first and biggest issue, which is repairable but frequently recurring, is motor failure. For the Zoe, the motor starts whining as early as 100,000 km, requiring preventive repair at a cost of around €1,000, while a new motor at a service center costs approximately €5,000. When inspecting the vehicle, test the Type2 charging and ensure that the car charges without interruptions. If charging stops, it could indicate an OBC failure.

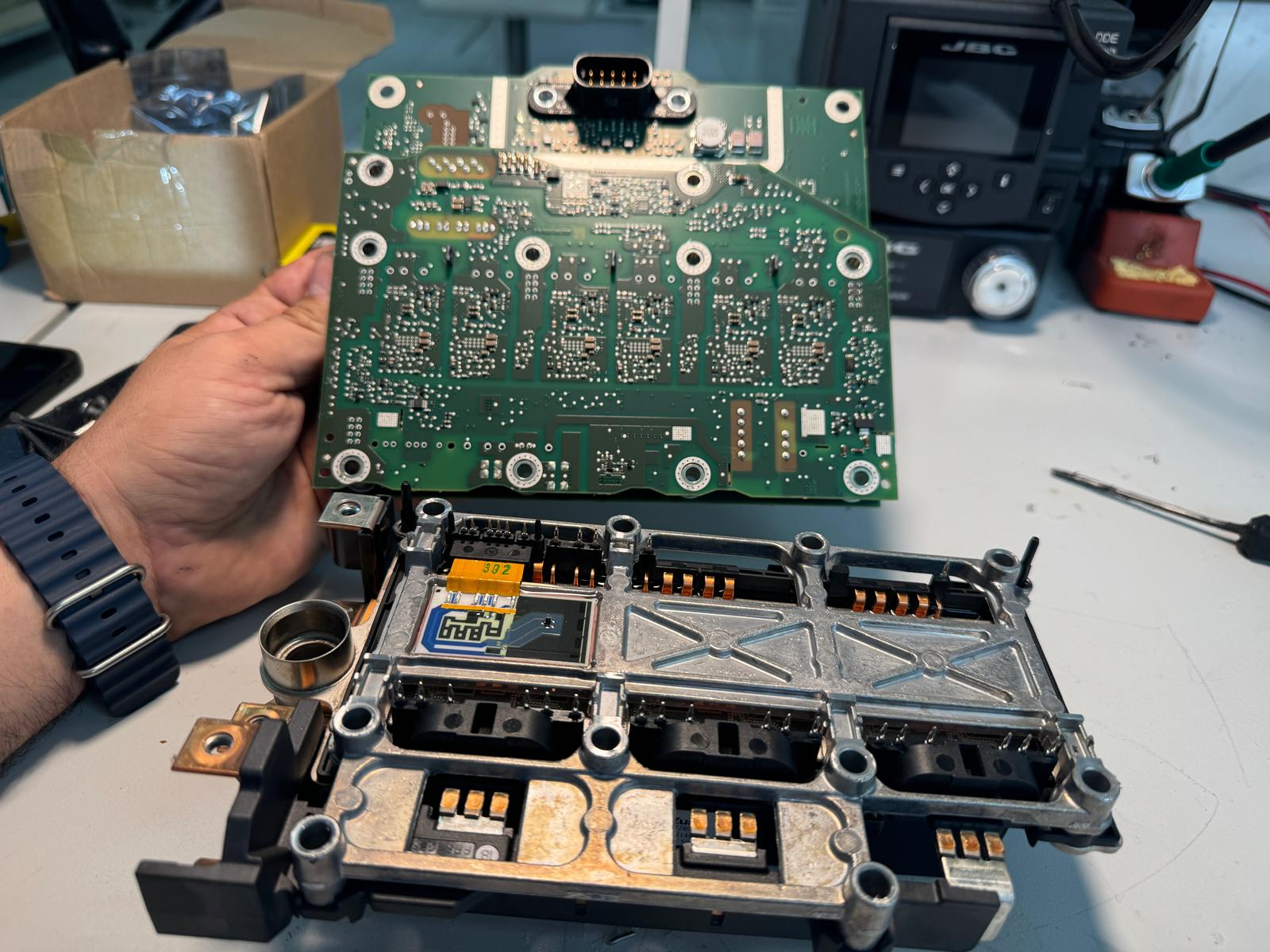

Another common issue in both the Twingo and Zoe is the failure of the DCDC inverter, which charges the small 12V battery. In some cases, this failure can even lead to module fires. The repair cost for the DCDC inverter is between €1,000 and €1,500. While we have not pinpointed the exact cause of this failure, we believe that a poor 12V battery is the most likely reason, so we recommend replacing it before every winter. The battery system uses LGX Pouch cells.

Expected minor battery failures – not documented Expected major battery failures – not documented Expected motor failure – 60,000-120,000 km

REPAIR: €1,200

NEW: €5,000

Preventive differential oil change every 50,000 km. OBC failure every 80,000 km:

REPAIR: €1,500

OEM: €1,500-2,000

DCDC inverter failure every 100,000-150,000 km:

AUTHORIZED SERVICE: €1,000

REPAIR: €1,000

Do not purchase this vehicle with your last funds—leave a reserve for potential surprises, although they are unlikely. And if they do occur, we are here to help. Despite potential unexpected repair costs, the vehicle is still more cost-effective than driving a diesel or hybrid.

Realistic range:

52 kWh: around 300-350 km

40 kWh: around 200-250 km

SUSTAINABLE: MEDIUM (Parts, Right to repair, Documentation, Diagnostic)

Unreliable powertrain

Reliable Battery system

YOYO XEV

A vehicle so rarely faulty that there’s not much to say or note about it, we include it here despite being a newer generation because it is a cheaper, more modern, and reliable substitute for the electric Smart 453EQ. It lacks the comfort and luxury of the Smart but comes with far fewer headaches due to costly failures. The battery system uses LFP PRISMATIC cells, which are very high-quality and reliable. They are resistant to deep discharge. The battery is easily connectable and replaceable. We have only one documented case where an owner left an almost empty vehicle unattended for several months, causing the battery to discharge deeply. We were able to revive and balance it, so replacement was not necessary. In the car and during driving, it is evident that this is a low-cost vehicle, categorized as L7, where speeds over 80 km/h are not achievable.

Battery failure – not documented Motor failure – not documented OBC failure – not documented

The prices of new parts are unknown. The vehicle is recommended but with some caution due to limited information. Based on existing data, this small city EV moped is very interesting and reliable.

Range: Approximately 100 km

MERCEDES EQS i EQE

Very new vehicles and the only ones from the EQ series that can be partially recommended, as they use a more advanced and reliable battery system with no reports of “programmed obsolescence” or, in other words, intentional design flaws. The vehicles are impeccably built both inside and out, and they are very comfortable. So far, we have no reports of failures in the electric motors or any other high-voltage systems.

The only thing we do know is that their batteries are very expensive:

- EQS: around €70,000 new

- EQE: unknown

Realistic range: (waiting for feedback)

SUSTAINABLE: Unknown (Parts, Right to repair, Documentation, Diagnostic)

CHINESE EV VEHICLES

The anticipated influx of Chinese electric vehicles is eagerly awaited, as the current offerings of fossil-fueled, hybrid, and EV models from Europe are generally of poor quality and long-term sustainability. We have not received any repair inquiries for Chinese vehicles, and Chinese manufacturers show strong respect for warranties.

Owners we indirectly know praise brands like MG, BYD, and other top names.

We have no documented cases of motor or battery system failures.

The only documented Chinese-origin EV we have worked on and continue to work on is ELI.

Full support to owners of Chinese electric vehicles.

SUSTAINABLE: Unknown (Parts, Right to repair, Documentation, Diagnostic)

VEHICLES WE WOULD NOT BUY

The first question is probably: Why? This text is not a holy scripture or an advisory guide, but rather a reflection on what these vehicles show us on the workbench, along with the reactions of their owners. These reactions represent a compilation of those problems, leading us to the question: Is an EV even worth it? Unfortunately, in some cases, the answer is no. Some manufacturers simply lack the tools to listen to feedback and create a quality product or address existing issues. Often, that isn’t even their goal, as a high-quality product might negatively impact their business model and bottom line. This stands in contrast to the core idea of e-mobility and the EU’s agenda for a cleaner environment. A faulty EV is waste, and if it cannot be repaired profitably, it isn’t sustainable. Owners of such vehicles are left with the lasting belief that EVs are a poor choice, generalizing this opinion to the entire industry, even though their decision may have been misguided by making wrong choise.

Manufacturers need to be encouraged to make changes, whether through consumers refraining from buying poor-quality products or through other forms of pressure. That’s why we are listing here only the worst examples of EV ownership for which we have documented evidence and owner testimonials.

Nissan Leaf – 1.gen i 2.gen

This vehicle is responsible for forming all diesel-oriented stereotypes against electric vehicles. It embodies the phrase “the whole battery needs to be replaced when it fails.” It has one of the worst chemical configurations in its battery system, with Pouch cells that are so problematic and irreparable that it’s shameful to even call this vehicle electric. We do not service them at all. The cells, due to the lack of thermal management, overheat and become permanently damaged, often involving all cells in the process. There are no higher-quality replacement cells available.

We have received information that even when thermal management for cooling and heating is installed, these batteries cannot exceed 150,000 km. There are known cases of them reaching over 200,000 km, but mostly in taxis operating gently on local routes. In such cases, the battery does not even have time to cool down as the vehicle starts a new workday immediately. These batteries perform best in consistent temperatures without significant thermal fluctuations.

The battery warranty is up to 100,000 km, while the warranty for degradation—not failure—extends to 160,000 km, which often misleads owners who believe it covers failures as well. The batteries are very dangerous due to their tendency to swell and the potential for self-ignition. In Norway and the USA, these vehicles were recalled, and buybacks were offered due to systemic issues, but this did not happen in Europe. There are almost no issues with the motor, apart from one reported case of motor whining at 180,000 km. The OBC (on-board charger) occasionally has problems but not frequently. A new OBC costs €8,000.

The most disappointing fact is that the Nissan Leaf has the most expensive original parts globally, even more expensive than Mercedes. The battery costs around €40,000, the OBC €8,000, and the motor about €10,000, making maintenance of existing vehicles feasible only through cannibalizing other cars.

More details can be found here: Nissan Leaf – Source of All Stereotypes

Expected major battery failure: 80,000-150,000 km

NEW: €18,000-€45,000

REPAIR NOT POSSIBLE – PREVENTION NOT POSSIBLE

Replacing a few swollen and overheated cells only extends the lifespan by a few months or 10,000-30,000 km, after which the battery system must be reopened, and the next row of damaged cells replaced. If we cannot perform a repair that is long-lasting, we do not attempt it at all.

Avoid this vehicle entirely due to the poor battery system, as it is unsustainable in the long term. The only suitable candidate would be someone who drives 5,000 km annually.

Realistic range depends on battery capacity and degradation.

SUSTAINABLE: LOW (Parts, Right to repair, Documentation, Diagnostic)

Smart 453EQ

One of the worst cars ever produced in 100 years of automotive industry:

https://evclinic.eu/2022/10/16/elektricni-eq-smart-453-cmart/

A vehicle we own has been through our lab alongside approximately 50 different vehicles, so we’ve seen nearly every possible failure. Almost every one of these failures costs around €5,000 at an authorized service center. The issue isn’t when an expensive failure occurs—we can solve that—but when we can’t, and you’re forced to go to an authorized service center where, for example, replacing the DCDC inverter will cost €5,000.

One recent case involved an owner whose motor inverter burned out, melting the rotor excitation wire. We knew the inverter was beyond repair, and since it contains the IMMO key data, installing a used part wasn’t an option. The owner had to visit an authorized service center, where they replaced the entire drivetrain for €5,000. Later, they discovered the rotor was also burned, so they had to replace the motor as well, adding another €6,500. In the end, for a Smart 453EQ with only 20,000 km, the total repair cost was around €12,000, which the owner had to pay.

All owners will face at least one major failure, with costs ranging from €1,800 (our DCDC repair) to a full drive module replacement at €5,000. The motor is similar to, but smaller than, the Zoe R drivetrain, and has more issues, as it may start whining or report a resolver error at just 50,000 km, resulting in an additional €1,400 expense.

For the vehicle to be cost-effective, it should cost less than €5,000 or come with some form of extended warranty, as the warranty for the motor and drivetrain lasts only 4 years or 20,000 km. The battery system with LGX Pouch cells has proven very reliable, with no documented cell replacements. However, the BMS has “programmed obsolescence,” with programmed failures and counters that require the entire system to be replaced.

And biggest problem is DCDC failure which should be recalled: https://evclinic.eu/2024/02/02/smart-453eq-fire-hazard-recall-needed/

Expected minor battery failure – BMS programmed fault: 5,000-50,000 km – €1,200

Expected major battery failure – not documented

Expected motor failure – 50,000-70,000 km

REPAIR: €1,200

NEW: €6,000

Preventive differential oil change every 50,000 km.

OBC failure every 20,000 km:

REPAIR: €1,800

OEM: €5,000

DCDC failure every 10,000-50,000 km:

AUTHORIZED SERVICE: €5,500

REPAIR: €1,800

Realistic range: 80-120 km.

SUSTAINABLE: LOWER THEN GROUND 0(Parts, Right to repair, Documentation, Diagnostic)

PEUGEOT CITROEN OPEL – STELLANTIS VOZILA

Vehicles that have greatly disappointed both us and their owners due to the poor quality of the drivetrain and other high-voltage components. The first major issue is that the general vehicle warranty is tied to the battery warranty, meaning that if you miss a scheduled service for something as simple as refilling the windshield washer fluid, you automatically lose the warranty on the motor and battery. For almost all Opel, Peugeot, and Citroën electric vehicles, from family cars to vans, the same or similar electric motor is used, which, due to poor construction, can fail as early as 12,000 km. We experienced this with a DS E-Tense model that, unsurprisingly, lost its warranty because the washer fluid was not refilled. A new motor costs €12,000. Other cases have also fallen under “warranty rape,” losing warranty coverage for battery failures for which even we did not have a solution. For example, a replacement battery for the e-Jumpy costs €8,000.

Cases of faulty batteries, motors, and OBC chargers (which are factory defects and under recall) often occurred at only 10,000 km. While these issues could be overlooked, it is particularly alarming that the manufacturer has no solutions, either software or hardware, and lacks adequate recalls or revisions for defective parts. In warranty cases, faulty parts are often replaced with equally defective new parts, and parts frequently do not arrive promptly, leaving owners waiting for months while still paying loan installments on their vehicles. Battery systems are highly unreliable, as any fault will first display a battery system error with an undefined code.

One notable example of such abuse and denial of warranty based on an arbitrary criterion involves an unresolved case where:

https://evclinic.eu/2022/10/03/stellantis-warranty-ra-pe-bully/

Second example of Right-to-repair abuse:

https://evclinic.eu/2024/10/31/if-youre-driving-a-stellantis-may-god-be-with-you-part-2/

https://evclinic.eu/2024/10/30/if-you-drive-a-stellantis-vehicle-may-god-help-you-part-1/

The battery system cells are PRISMATIC LFP or NMC cells across almost all platforms, just configured and packaged differently.

We have around 40 documented cases of extremely poor experiences with all EV vehicles from the same group, including the Opel eCorsa, e206, DS, and others from their commercial lineup. It is crucial that your experience with an EV aligns with your expectations, and for these vehicles, no one can convincingly claim they are better than a Tesla, a diesel Audi, or any gasoline vehicle. You need to be exceptionally brave and enthusiastic to own one. For those who doubt this, just search for errors: P1069 and P106A.

Motor failures occur as early as 10,000 km

OBC failures by 20,000 km

Battery failures starting at 5,000 km.

SUSTAINABLE: ZERO (Parts, Right to repair, Documentation, Diagnostic)

VW ABTe – Transporter i Caddy

This is an unprecedented failure created out of VW’s obligation to launch an electric vehicle to balance CO2 emissions and offer something to their commercial lineup under ABT’s direction, resulting in a 2.5-ton disaster. They removed the diesel engine and added an electric one, not connected through the differential but through a DSG transmission, so you have an electric vehicle that shifts gears and jerks as you drive. While we can joke about this, the reality is unfortunate for fleet owners who, due to incentives, had to choose something electric and opted for VW based on brand reputation, only to regret it later when the vehicle incurred €28,000 in damages for a new battery at just 10,000 km. The warranty was not honored because they missed a routine service at 10,000 km for brake fluid and windshield washer fluid replacement.

All those who owned this vehicle have stated that they would never buy electric again, and their experience justifies that sentiment, which should serve as a message to manufacturers: produce quality vehicles for consumers, not defective products for the market. Additionally, warranty terms urgently need to be revised to decouple general warranty and service intervals from the battery warranty, as batteries do not have regular service requirements. The battery system is composed of PRISMATIC NMC Samsung SDI cells.

Battery failure can occur as early as 10,000 km.

Realistic range: 150 km.

SUSTAINABLE: ZERO (Parts, Right to repair, Documentation, Diagnostic)

JAGUAR iPace

A vehicle that has disappointed everyone. The poor quality and unreliability of the drivetrain are so catastrophic that, in addition to the manufacturer lacking solutions for several recurring factory defects, they are unable to issue revisions or conduct adequate research into existing issues with the battery, DCDC inverter, and OBC charger. We have received widespread complaints from owners stating that their vehicles, even under warranty, have been towed multiple times to authorized service centers and left there for months without resolution. Many who bought this EV have permanently given up on transitioning to electric vehicles and returned to older diesel models. This vehicle is an absolute disappointment and highly concerning due to a serial battery defect that causes it to catch fire during fast charging. We have 13 documented owner complaints, all with the same pattern: the authorized service center has no solution, they attempt a fix, and within two days, the vehicle breaks down again and is towed back to the workshop.

We have not accepted any of these vehicles for service because we believe that factory defects that pose a danger should be resolved by the manufacturer, not us.

EV SHORT CONCLUSION

The most problematic battery systems are those with POUCH cells, which often require the replacement of multiple cells or the entire battery system. The most reliable battery systems use CYLINDRICAL cells, followed by PRISMATIC cells.

The longest-lasting electric motors have ceramic rotor bearings and rotor cooling, featuring floating bearings for discharging eddy currents from the rotor (only found in Tesla). The least reliable motors have air-cooled rotors without active rotor cooling.

Best electric motors for maintenance: INDUCTION Most challenging electric motors for maintenance: PMSM

Vehicles our engineers drive or would choose to drive:

Me: S100 RWD Tuned, Fiat 500e USA, Audi eTron GT, Lucid Air

Marko: x

Domagoj: Tesla S 100D, Renault Zoe Q210

Mario: Smart 451ED, Tesla S 100D

HYBRIDS IN GENERAL

This topic, which we have repeatedly discussed and disproven with examples of unsustainability, has been updated and previously published, but we reiterate: WE DO NOT RECOMMEND ANY HYBRID—either go fully electric or stick with pure gasoline: https://evclinic.eu/2023/07/15/hybrid-apocalypto-deceptive-anti-electrification-and-unsustainability/ For individual examples, visit this link: https://evclinic.eu/hybrid/

Example of a battery replaced at 90,000 km, only to need a full replacement again at 150,000 km: https://evclinic.eu/2024/05/21/mercedes-hybrid-unsustainable-trash/

Hybrid systems like REX (range extender or REEV), where the primary power comes from the electric motor and battery, with an auxiliary engine as a backup, have proven to be the only sustainable and long-lasting options. BMW demonstrated this brilliantly with the i3 and i8 models, which were based on this idea—the battery is large enough to handle loads without significant wear and tear on the system.

However, all hybrids we have serviced have shown that their batteries are more expensive than those in electric vehicles, ranging from €10,000 to €32,000 for a Range Rover. The worst part is that these batteries were often replaced under warranty before 100,000 km (BMW, Mercedes, Range Rover, VAG, etc.), only to require replacement again at 200,000 km when they are no longer under warranty. Owners who naively believed they were making a cheaper choice by importing hybrids from Germany are often faced with battery replacement costs higher than the price of a new EV.

Additionally, many uninformed owners believe that lithium-ion batteries can be “regenerated” for a modest fee of €69. The reality hits hard when they visit 20 service centers, 39 “experts,” and several DIY enthusiasts, only to be told that a new battery is needed. Battery regeneration does not exist, and cells are often so swollen and degraded that they are not even suitable for “second life” applications. The phrase “the whole battery needs to be replaced, and it’s more expensive than the car itself” actually originated with hybrids (and the Nissan Leaf). Due to media misinformation, many people choose hybrids to “avoid battery problems” in EVs, even though EVs, in reality, have the fewest battery issues because their batteries are larger, overbuilt, and often more durable over time and mileage.

For a hybrid to be sustainable with a long-lasting battery system, it should have at least a 40-50 kWh battery. Then, if you always drive on electricity, you’ll start wondering why you even have an ICE engine under the hood, which only adds weight and reduces the EV’s range.

Of all hybrid systems, only Toyota, with the first generations of Prius, has proven sustainable, though not necessarily long-lasting. Toyota has managed to reduce the cost of replacing its NiMH BLADE battery systems to around €1,900 at authorized service centers, which is commendable. However, the praise stops there, as we noticed during each battery maintenance and repair that something was off. When a battery pack that triggered an error (usually in cold weather) arrives, we open it and start detailed measurements. The battery system, for example, has 28 “cells,” but these are actually BLADE packs composed of five or more cells connected in series, enclosed in plastic/aluminum, appearing as one large cell. The issue is that Toyota’s system monitors voltage and balances only after every fifth cell (meaning it cannot detect overvoltage or undervoltage between them), and there are only 2-3 temperature sensors across the entire battery system. If a cell without a sensor overheats, it can trigger a chain reaction, “cooking” adjacent cells without the BMS detecting it.

This poor design leads to early battery damage from overheating, often as early as 100,000 km. It was suspicious why no error was indicated. Toyota cleverly increased system tolerance and suppressed error signaling so that an error only appears when a battery unit’s capacity drops to 0.5 Ah from the nominal 5.5 Ah—meaning only when SOH has degraded by 90%. Meanwhile, you are driving with significantly reduced fuel savings and a degraded hybrid system. For two different taxi fleets, we have done battery restorations, and many batteries had to be fully replaced or opened for cell replacement and repacking after just 200,000 km. The Auris is somewhat more durable; we had an example with over 250,000 km and completely damaged 6-7 cells and around 50% battery degradation even after repairs and refreshing.

One cell, when measured, goes into undervoltage and rapidly overheats—no diagnostic tool or cell regeneration device can detect this, except for an IR camera or by measuring the voltage curve.

Additionally, there is widespread fanatical belief that “the car still has its original battery” and has traveled 500,000 km because all taxi drivers use them. This is true in the sense that the battery cover remains original, but almost all cells have been replaced multiple times. We have repeatedly confirmed that nearly all taxi vehicles have had their batteries opened several times, as the cells were marked with 3-4 different colored markers and serial numbers. So, the only original part is the battery cover.

Other hybrids, if they can even be called that, are MILD hybrids—expensive to maintain and problematic. Only Suzuki has proven to be very reliable.

EXAMPLE IN LINK: https://evclinic.eu/2024/09/05/toyota-huge-battery-degradation-taboo-topic/