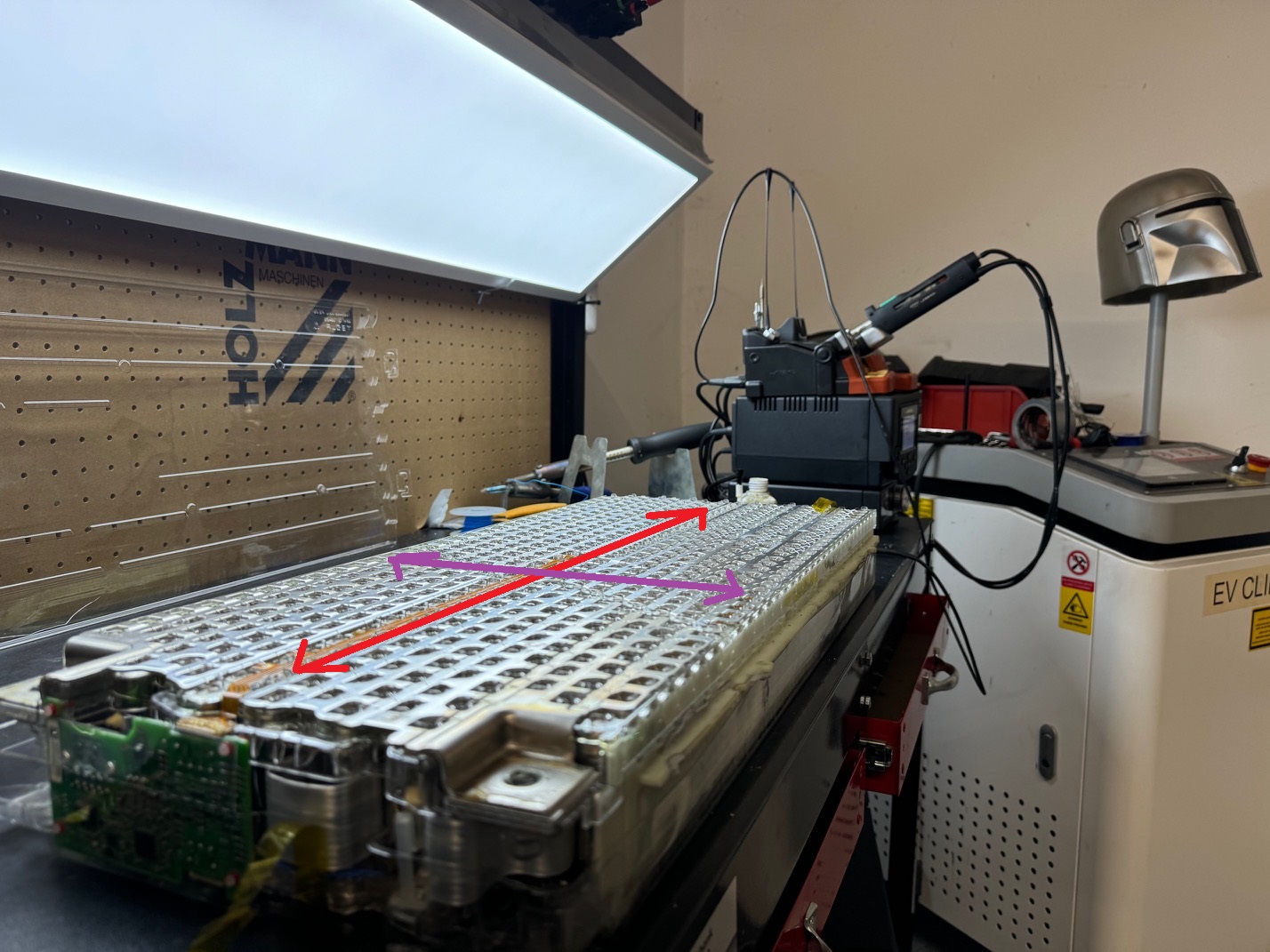

I can’t believe it, but the 100 kWh pack, which has been refined from previous generations, has failed on me (and it’s not the cells causing the issue). The problem lies in a flaw we’ve been observing in fossil-fueled vehicles for the past 20 years: aluminum wire bonding. The same problem that TEMIC has failed, either by accident or on purpose, to resolve in the automatic transmissions of VAG and MB over the last 20 years, affecting 80 million vehicles, is now appearing in the 100 kWh battery. The only manufacturer we’ve noticed who has nearly perfect ultrasonic wire bonding is BOSCH, as they adhere to some “secret” recipes for long-term reliability that we observe in the aftermarket. Meanwhile, Temic, Conti, and others continue to make the same mistakes, as does Tesla in this specific case, where they didn’t account for the thermal expansion of the battery module both in width and length, nor the potential galvanization of the “wire sense” flat cable connection. Designing a battery system without any flaws is impossible, but if you ask me, I certainly wouldn’t have failed in these connections, where the wire is too short from the terminal plate to the flat cable used to measure the voltage of one group. All 16 modules in the battery system had 5 to 7 damaged connections, and the ones that suffered the most were those parallel to the longer part of the module (red line), where the expansion was greatest, resulting in the most damaged groups. Based on previous documented cases, which we couldn’t address because they were under warranty, it seems that all 100 kWh batteries will fail between 150,000 and 250,000 km. The good news is that they will never suffer from classic moisture penetration, as they have a new generation of vapor-permeable valves, lack fuse covers on the top side, and don’t have some of the other faults of previous generations (our trade secret). Furthermore, the “batteries” will never fail, i.e., the individual cells, as we estimate that the cells themselves can last over 600,000 km. However, a repair of the entire battery due to unaccounted thermal expansion will likely be necessary, but after that, it will never have this problem again because we fix it permanently!

This 100 kWh battery system has a black metal cover, meaning it is a REMAN battery (already serviced), but the problem has been documented on non-REMAN systems as well. The side effects I’ve noticed include the range dropping overnight more than usual, but this is not a rule. The only clear indication is the drop in BMS parameters by 4 kWh, from 88 to 84 usable. As a result, the range parameter in kilometers on the dashboard decreased after two consecutive charges. A third parameter was visible through measurements with our EVC Explorer tool, where one module showed noise in the voltage measurement. The worst part is that the battery started failing on the highway, but AIDBOX saved the day, acting as life support to get us to our destination. For all other Tesla 100 kWh battery owners, most of whom are still under warranty, an essential battery system service awaits them, which we have only just discovered.

Repair is not easy and cheap, soldering is not possible because it is aluminium (thermal expansion cracks soldering attempts), 10000-15000€ equipment needed beside 40-60 labor hours to finish it. This should not be done by any DIY workshops or any other untrained personel. You risk destroying battery pack.

Error code: BMS_f107, BMS_w177

Affected cars: Model X and S from 2016 – 2021

100D P100D Longrange