It’s time for an honest review: With Stellantis OBC we have observed frequent technical issues with several EV models, which raises questions about their long-term reliability. The level of questionable engineering in their designs borders on the absurd, and it’s time to highlight the issues where owners ultimately pay the price. We’re all aware of the shortcomings in their diesel, gasoline, and hybrid vehicles, but what’s happening with their EVs is truly unacceptable. These problems could discourage buyers from EVs and lead them back to diesel – an unfortunate outcome that benefits no one

Our experience has exposed a range of problems, from restricting “right to repair” access for independent workshops (blocking schematics, software, updates, parts) to the absence of essential tools and documentation. Their support practices appear to violate the spirit of EU Regulation 2018/858, Article 61, by limiting independent repair access. Warranty conditions are extremely strict – for instance, skipping a minor service (like a wiper change) can void the battery warranty – which customers find unreasonable.

The situation is even worse for official service centers, whose technicians receive inadequate training, lack reliable hotline support, and often resort to blindly swapping parts at the owner’s expense. And even when they can identify the problem, replacement parts are frequently unavailable, leading to delays of 2-6 months, which is especially damaging for businesses left without a replacement vehicle under warranty. Worst of all are the warranty terms—these conditions border on extortion. They tie the vehicle’s overall warranty to specific components; for example, skipping a windshield wiper change could void the battery warranty, even during critical recalls where they refuse to replace faulty parts.

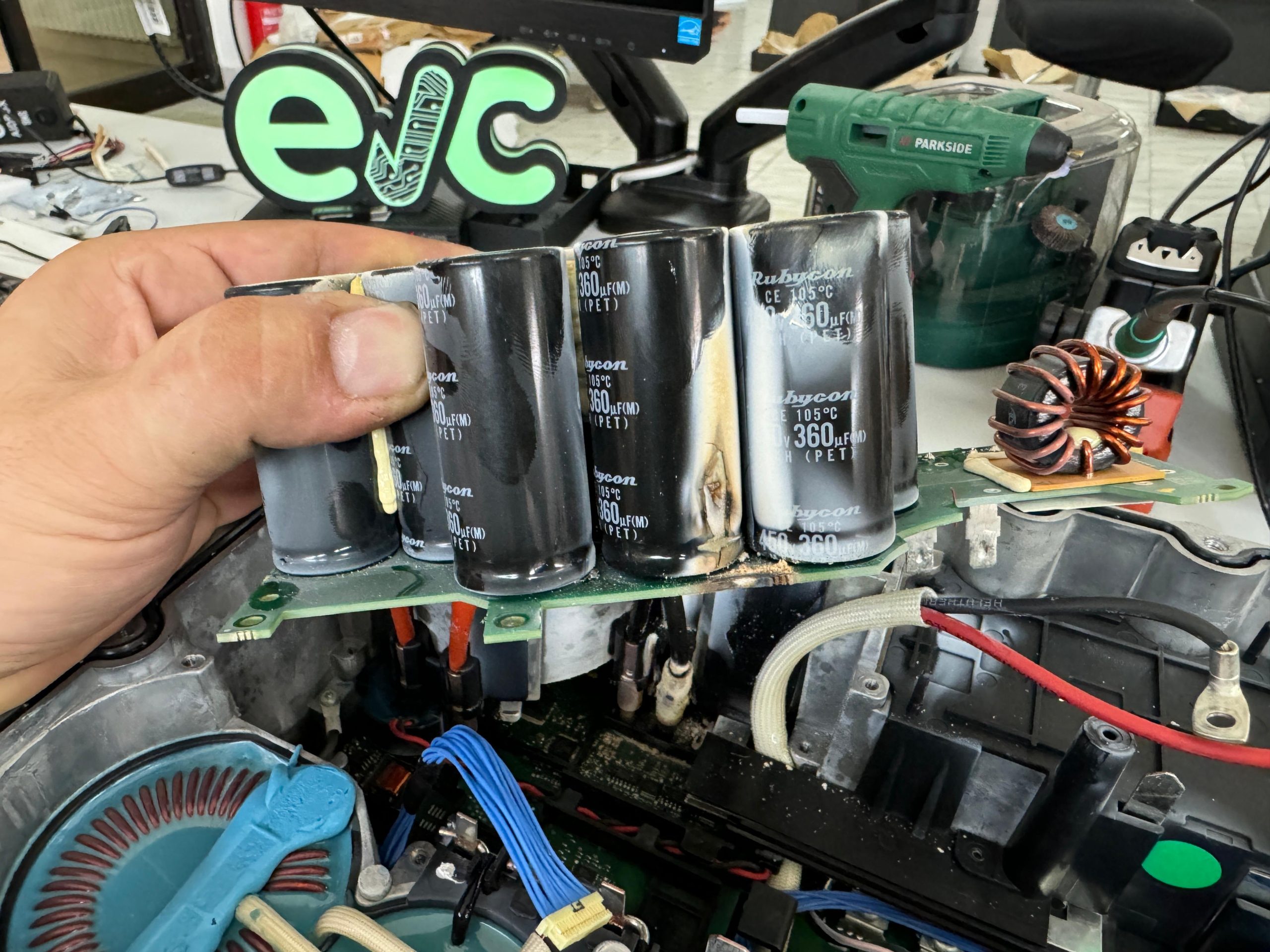

We’ve documented three cases of catastrophically flawed MAHLE OBC and DCDC units integrated into a single module, with eight circuit boards that overcomplicate the system to an extreme. The final IGBT board is epoxy-bonded to the cooling plate along with the DCDC inverter, with almost every board running its own microcontroller. In two cases, damage was undetectable, but Type 2 charging simply didn’t work. In one case, an inductor wire to the IGBT output burned out. We couldn’t repair any of these units after three attempts. For the second part, we’ve been waiting six months, and despite it being a factory defect, it’s neither covered by warranty nor recognized in a recall, leaving owners no option but to switch manufacturers or face potential financial ruin. This issue affects all Peugeot, Citroën, Opel, Toyota, and DS vehicles—and it’s just the beginning.

It’s as if they’re making EVs so that you’ll hate them.

Part number: H-20679-01, 03196727, MAHLE

Processor: Sak-TC234L

Error: Type2 doesnt charge

OEM : 2200€ (6 months waiting time)

EVC: –

for now, the best doc I found come from Nissan and Tesla. I would add Opel (ampera) among that with incompressible documentation that do not help to repair.

I have the same problem. Do you have a video of the disassembly process or any tips on how to disconnect the boards?

Dont dissasemble it, PCB cracks and hard to detects it.

We have only cloning procedure.

Regards

Good wasn’t with us…

After buying a Peugeot e-Rifter first problems occurred with the on-board loader (changed by dealer on warranty), next problem 1/2 year later , main battery failed (changed by dealer on warranty but nothing documented in their systems), car in repair 3month) latest problem “engine” defect after 37000 km of mileage, car in repair almost 5month, bill ~10000€ with goodwill regulation on 75%.

Oh boy never ever a car out of these concern.

🙁 You are not only victim. Every owner of stellantis is a victim

What a Horror Design !

12 Diods would be enough for 3 phase rectifier .

It looks like the best Friend of this Designer, is a producer for Semiconductors .

Each Part and Contact is source for Heat and possible failures.

And the worst Design Fault, is that the OBC need a individual FIN Code, without any usefull reason . No Brand Garage is able to code it , there is no chance for second market , a behaviour which means aditional loss of Value for owners . the success of Opel was: the interchangeability of Parts, Manta-Rekord -Kadett- Ascona . Hey Stellantis , Timebelt in Oil is also Designfailure .